— gaseous fire suppression

Manufacturing Facilities

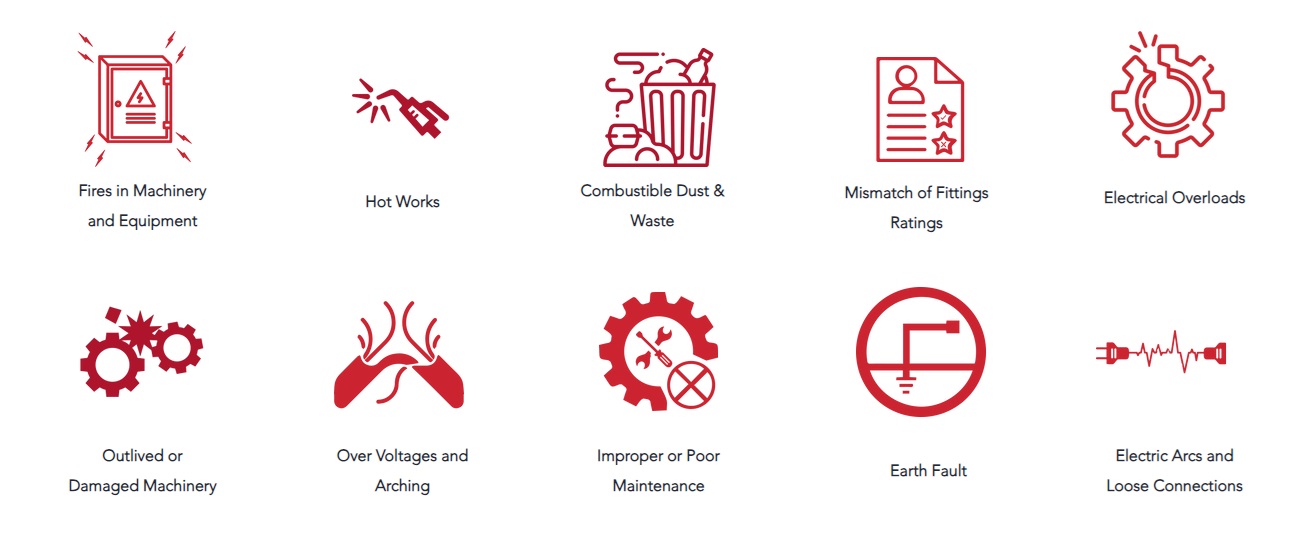

— Dangers in Manufacturing

Fire Hazards

Manufacturing units are the heart of industrial production, where raw materials are transformed into finished goods through a variety of processes and machinery. Despite their crucial role in the economy, these environments are inherently prone to fire hazards. The combination of high-powered equipment, flammable materials, and complex production processes creates a setting where the risk of fire is ever-present.

Electrical faults, overheating machinery, chemical reactions, and human error can all lead to devastating fires that endanger lives, disrupt operations, and cause significant financial losses.

Recognizing and mitigating the fire dangers in manufacturing units is essential to ensure the safety of workers, protect valuable assets, and maintain continuous production. A proactive approach to fire safety, encompassing prevention, detection, and emergency response, is critical in managing these risks and securing a safe manufacturing environment.

— Manufacturing —

Fire Facts

The total cost of fires in manufacturing premises in England in 2021/22 was £1.1 billion. This included the cost of damage to property, the cost of business interruption, and the cost of fighting the fires.

The Regulatory Reform (Fire Safety) Order 2005 requires manufacturing businesses to take reasonable steps to reduce the risk of fire and to ensure that people can safely escape in the event of a fire.

There were 17,874 fires in manufacturing premises in England in 2021/22.

— Gaseous Suppression

We can Protect your Space

To protect a manufacturing facility from fire, several key factors need to be considered and addressed. Here are the main aspects to be aware of:

- Fire Prevention Measures

- Electrical Safety:

- Regularly inspect and maintain electrical systems to prevent faults.

- Avoid overloading circuits and ensure proper grounding.

- Use certified and high-quality electrical components.

- Proper Storage of Flammable Materials:

- Store flammable chemicals and materials in designated, safe areas away from ignition sources.

- Use appropriate containers and follow regulations for hazardous materials.

- Maintenance of Machinery and Equipment:

- Regularly service and maintain machinery to prevent overheating and mechanical failures.

- Keep machinery free from dust and debris, which can act as fuel.

- Housekeeping:

- Maintain a clean work environment to prevent the accumulation of flammable materials.

- Dispose of waste materials properly and promptly.

- Fire Detection Systems

- Smoke and Heat Detectors:

- Install smoke and heat detectors throughout the facility, especially in high-risk areas.

- Ensure detectors are connected to a central alarm system for immediate response.

- Regular Testing and Maintenance:

- Conduct routine tests of fire detection systems to ensure they are functioning correctly.

- Replace batteries and service detectors as needed.

- Fire Suppression Systems

- Sprinkler Systems:

- Install automatic sprinkler systems designed for the specific hazards of the facility.

- Ensure the system is regularly inspected and maintained.

- Fire Extinguishers:

- Place fire extinguishers at strategic locations throughout the facility.

- Train employees on the proper use of different types of extinguishers.

- Specialized Suppression Systems:

- For facilities handling flammable liquids or gases, consider using specialized suppression systems like foam or gas-based extinguishers.

- Emergency Response Planning

- Evacuation Plans:

- Develop and clearly mark evacuation routes and emergency exits.

- Conduct regular fire drills to ensure employees are familiar with evacuation procedures.

- Employee Training:

- Train employees on fire prevention, detection, and response.

- Ensure everyone knows how to use fire extinguishers and the location of emergency exits.

- Emergency Contacts:

- Maintain an updated list of emergency contacts and ensure it is easily accessible.

- Environmental Control

- Temperature and Humidity Monitoring:

- Monitor and control the temperature and humidity to prevent conditions that might contribute to fire risk.

- Ventilation:

- Ensure proper ventilation to disperse flammable vapors and prevent the buildup of hazardous gases.

- Compliance and Inspections

- Adherence to Regulations:

- Follow local, state, and federal fire safety regulations and codes.

- Stay updated on changes in fire safety standards and implement necessary adjustments.

- Regular Inspections:

- Conduct regular fire safety inspections to identify and address potential hazards.

- Work with local fire authorities to ensure compliance and preparedness.

By being aware of these factors and implementing comprehensive fire safety measures, a manufacturing facility can significantly reduce the risk of fire and protect both its employees and its operations.

— Gaseous: Suppression

Resources

Scroll through our supporting articles: